Hand & Lock have partnered with Coloreel to test and develop the latest machine embroidery technology. Described as the biggest innovation in embroidery for 30 years, it has the potential to help reduce the 215 trillion litres of water wasted by the fashion industry every year.

The Swedish company’s Instant Thread Coloring Unit allows machine embroidery to be more vibrant, creative and sustainable. Standing over two metres tall, the unit contains a single spool of white thread and an array of inkjet cartridges, micro dryers, washers and lubricants.

Installed above a digital embroidery machine, it replaces the need for multiple coloured spools. Using unique technology, the machine can colour a single cone of recycled white polyester as the embroidery is being made.

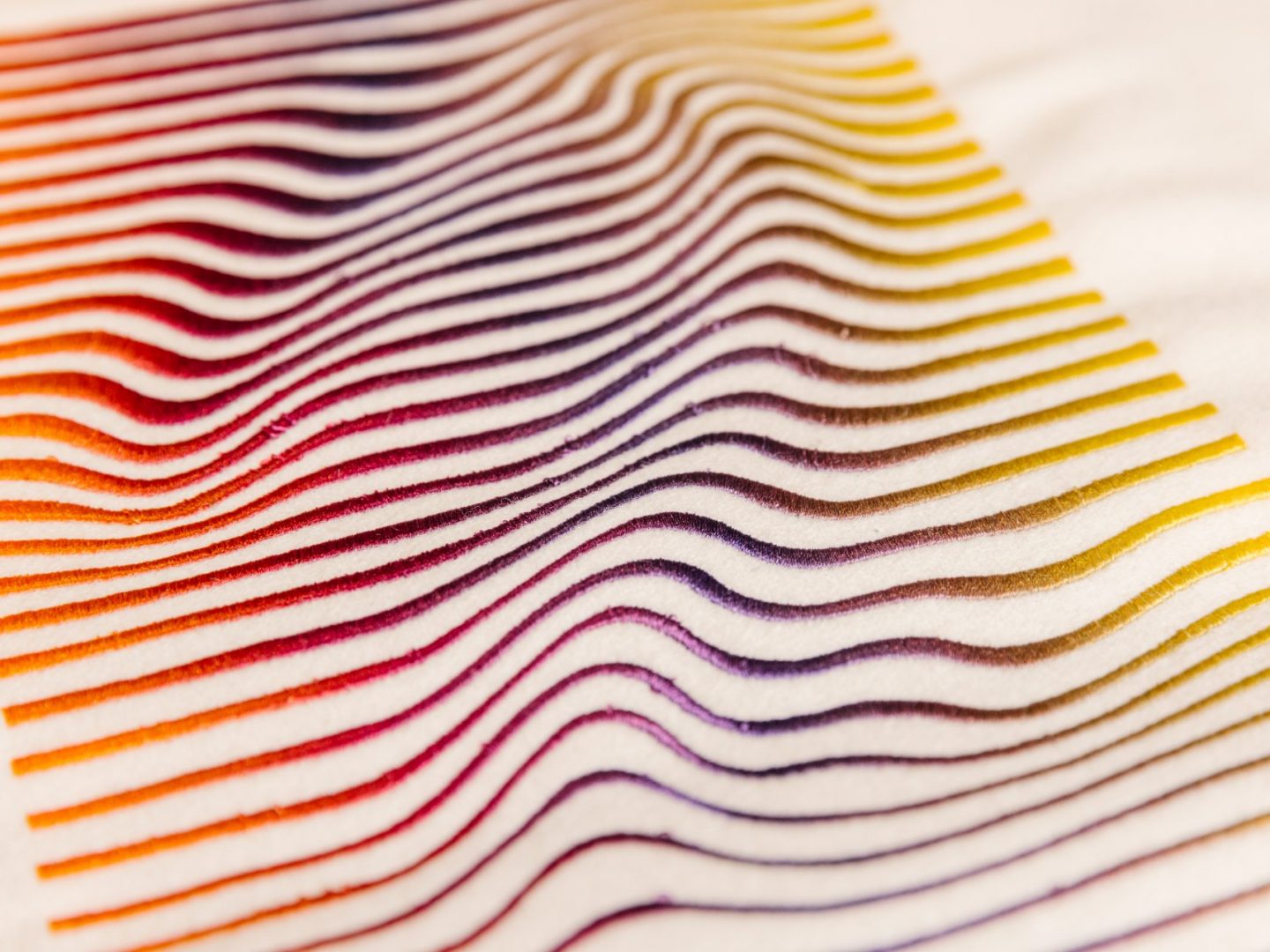

The digital machine embroidery designers at Hand & Lock use the Coloreel for the most colour intensive commissions. It allows embroidery designers to achieve precision gradients and natural ombre effects. Where a complex embroidery might be limited to 15 separate spools of colour, the Coloreel unit can apply 1000s of different colours using only one spool.

Coloreel allows for greater creativity and more beautiful embroidery.

For the designer and the customer, the main benefits are unlimited colours, less complex colour management and less human error. For the planet, the benefits are less thread waste, less water waste and less chemical pollution. Using a built-in dying process, the Coloreel unit reduces the water use associated with chemically dyed threads.

For brands and customers that aspire to high levels of responsibility and sustainability, Coloreel at Hand & Lock offers a much-needed step towards reducing our collective environmental impact.